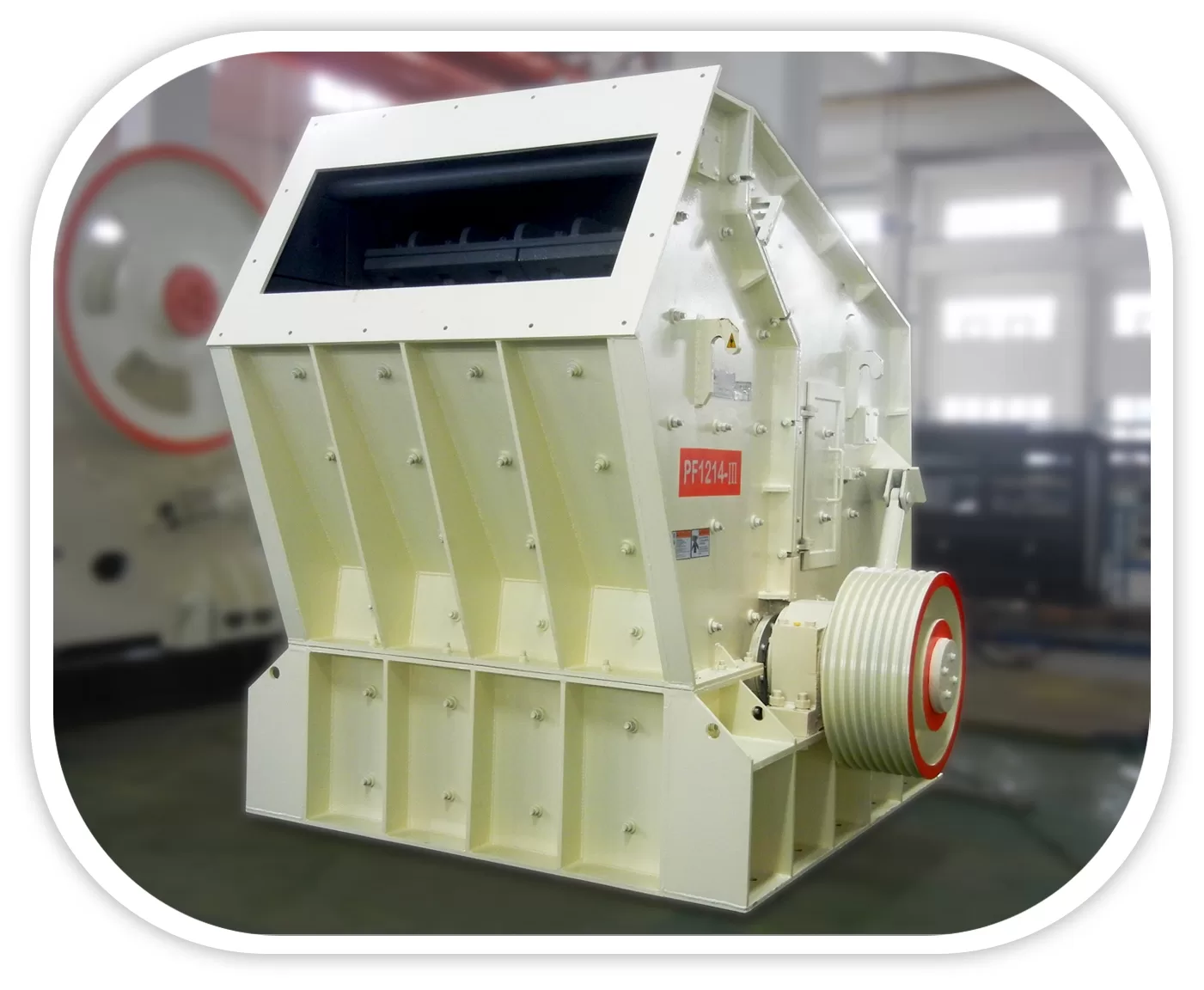

تأثير محطم

تتوفر مجموعة متنوعة من النماذج | احصل على قائمة الأسعار المجانية!

- حجم جزيئات التغذية: ≤ 1000mm

- السعة: 15-850 طن / ساعة

- 【المواد القابلة للتطبيق:】الحجر الجيري ، الجرانيت ، الرخام ، البازلت ، خام الحديد ، حصى الأنهار ، الصخر الزيتي ، الحجر الجيري ، الفحم ، الحصى ، مخلفات البناء.

- المجالات القابلة للتطبيق:】تستخدم على نطاق واسع في تكسير الخامات المختلفة ، والسكك الحديدية ، والطرق السريعة ، والطاقة ، والأسمنت ، والكيماويات ، والبناء ، وغيرها من الصناعات.

ما هي الكسارة الصدمية؟

Impact crusher is a kind of crusher which utilizes impact energy to crush materials. It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with feed size not more than 500mm and compressive strength not more than 350MPa, and is widely used in all kinds of ore crushing, railroad, highway, energy, cement, chemical, construction and other industries. It adopts updated manufacturing technology and unique structural design. The finished product is cubic with no tension or cracks. Our impact breaker series is divided into two series: two-chamber and three-chamber series.

تطبيقات الكسارة الصدمية

Impact crushers are versatile machines that have a wide range of applications across various industries. Here are some of the main applications of impact crushers:

- التعدين واستغلال المحاجر: Impact crushers are commonly used in mining and quarrying operations to crush rocks, ores, and other hard materials. They are particularly effective in reducing large rocks to smaller, more manageable sizes.

- إجمالي الإنتاج: In the construction industry, impact crushers are used to produce aggregates such as sand, gravel, and crushed stone. These materials are used in concrete, asphalt, and other construction applications.

- إعادة تدوير: Impact crushers are also extensively used in recycling applications, where they can process concrete, asphalt, bricks, tiles, and other waste materials. This helps to reduce the amount of material sent to landfills and allows for the reuse of these materials in new construction projects.

- إدارة المخلفات: Impact crushers can be used to reduce the volume of waste materials, making them easier to transport and dispose of. They can handle a variety of waste types, including plastics, wood, paper, and more.

- هدم: In demolition projects, impact crushers can be used to process concrete, bricks, and other materials from demolished structures. This allows for the recycling of these materials and reduces the amount of waste generated by demolition projects.

- تطبيقات أخرى: Impact crushers can also be used in a variety of other applications, including glass recycling, ceramics production, and the processing of non-metallic minerals.

The versatility and high efficiency of impact crushers make them a valuable asset in many industries that require material reduction and recycling.

مبدأ عمل الكسارة الصدمية

Here is a brief overview of the working principle of an impact crusher:

- الأكل: The material to be crushed is fed into the impact crusher through a feeding inlet or hopper. This feeding process can be automated or manual, depending on the crusher model and the specific application.

- سحق تأثير: Inside the crusher, there is a rotor or hammer assembly that rotates at high speed. This rotor or hammer assembly has impact hammers or blow bars that are mounted on it. As the rotor rotates, the hammers hit the material that is falling or passing through the crusher, applying impact forces on the material. The high-speed rotation and impact forces cause the material to break into smaller pieces.

- Rebounding and Secondary Crushing: The broken pieces of material rebound from the crusher walls or anvils (if present) and collide with each other or with the hammers again, undergoing further crushing. This process of rebounding and secondary crushing continues until the material is reduced to the desired size.

- Screening and Discharge: The crushed material is then passed through a screening mechanism, which separates the material into different size fractions based on the size of the openings in the screen. The material that meets the desired size specifications is discharged from the crusher through a discharge outlet, while the oversize material is recirculated for further crushing.

- نظام التحكم: Modern impact crushers are equipped with advanced control systems that monitor and regulate various parameters such as rotor speed, feed rate, and discharge size. These control systems ensure efficient and reliable operation of the crusher.

مبدأ عمل الكسارة الصدمية

المزايا الهيكلية للكسارة الصدمية ZDM

- البناء الثقيل: Constructed with robust materials and components for durability in harsh crushing environments.

- Optimized Crushing Chamber: Chamber design maximizes crushing efficiency while minimizing wear.

- Adjustable Gap: Allows for adjustment of crushing gap based on material properties and output requirements.

- سهولة الصيانة: Design facilitates easy cleaning and replacement of wear parts, minimizing downtime.

- Integrated Screening System: May feature an integrated screening system for classifying crushed material to meet different size specifications.

- نظام تحكم متقدم: Advanced control system may be available to monitor and adjust key parameters for efficient and stable operation.

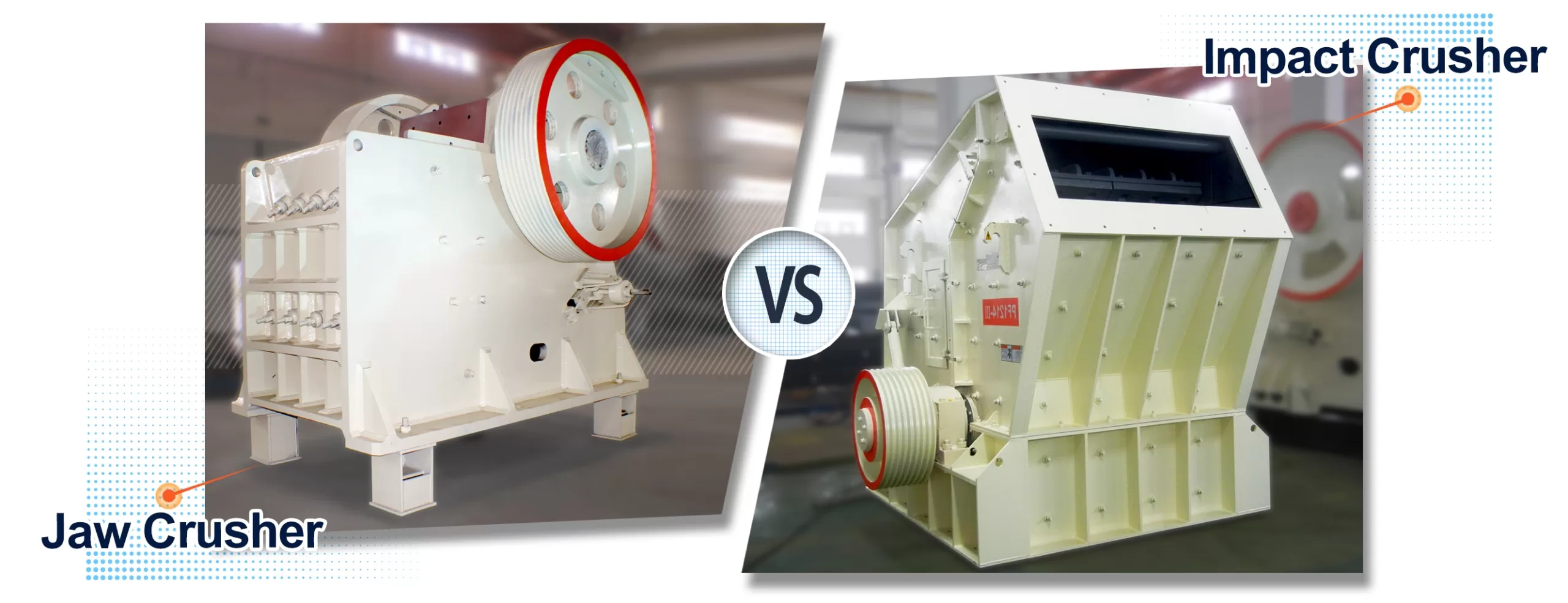

الكسارة التصادمية مقابل الكسارة الفكية

| المواصفات الخاصه | كسارة الفك | تأثير محطم |

|---|---|---|

| حجم فتح المدخل | نماذج متعددة بأحجام مختلفة | حجم أكبر |

| مبدأ العمل | ضغط | تأثير |

| تطبيق | عملية التكسير الأولية | عملية التكسير الثانوية |

| تكيف | قابلة للتكيف مع أحجام مختلفة من المناجم والنباتات | أقل قدرة على التكيف |

| الاستخدام في مصنع تكسير الحجارة | عادة ما تستخدم | يمكن استخدامها مع الغربال الاهتزازي والمغذي الاهتزازي |

| الاستخدام في مصنع صنع الرمال | يمكن استخدامه مع آلة صنع الرمل ، وغسالة الرمل ، والشاشة ، والمغذي | غير شائعة الاستخدام |

الكسارة التصادمية مقابل الكسارة الفكية

المواصفات العامة

| الموديل | المواصفات الخاصه (مم) | افتتاح (مم) | الحد الأقصى حجم التغذية (مم) | الطاقة الإنتاجية (العاشر) | الطاقة (كو) | أوفرول بعد (L × W × H) (مم) | الإجمالي الوزن (ر) |

| PF-1007 | Φ1000 × شنومكس | 400 × 730 | 300 | 30-70 | 4P 37-45 | 2330Ã-1660Ã-2300 | 12 |

| PF-1010 | Φ1000 × شنومكس | 400 × 1080 | 350 | 50-90 | 4P 45-55 | 2370Ã-1700Ã-2390 | 15 |

| PF-1210 | Φ1250 × شنومكس | 400 × 1080 | 350 | 70-130 | 6P 110 | 2680Ã-2160Ã-2800 | 17.7 |

| PF-1214 | Φ1250 × شنومكس | 400 × 1430 | 350 | 80-180 | 6P 132 | 2650Ã-2460Ã-2800 | 22.4 |

| PF-1315 | Φ1320 × شنومكس | 860 × 1520 | 500 | 100-280 | 6P 200 | 3180Ã-2720Ã-3120 | 27 |

| PF-1320 | Φ1300 × شنومكس | 993 × 2000 | 500 | 140-380 | 6P 250 | 3220Ã-3100Ã-3120 | 34 |

| PF-1520 | Φ1500 × شنومكس | 830 × 2040 | 700 | 200-550 | 4P 315-400 | 3959Ã-3564Ã-3330 | 50.6 |

| PF-1820 | Φ1800 × شنومكس | 1260 × 2040 | 800 | 400-800 | 4P 630-710 | 4400Ã-3866Ã-4009 | 83.21 |

المنتجات ذات الصلة

كسارة الفك

كسارة الفكالكسارة الخشنةالكسارة الفكية تستخدم بشكل رئيسي في التكسير المتوسط الحجم للخامات المختلفة والمواد السائبة. يمكنها سحق المواد بقوة ضغط لا تزيد عن 320Mpa. هناك نوعان من طرق التكسير…

الرمال ماكينة

آلة صنع الرملالتكسير الدقيقاحصل على السعر والدعم آلة صنع الرمل مناسبة للمواد الخام الناعمة أو المتوسطة الصلابة والمواد الخام شديدة الصلابة بصلابة لا تزيد عن 320 باسكال. كما أننا نسميها عادةً آلة صنع الرمل VSI. وله خاصية…

مخروط محطم

احصل على السعر والدعم Whatsapp +8618637198006 البريد الإلكتروني: zd-machine@kssb.cn احصل على السعر اترك رسالة مبدأ العمل:،

كسارة زنبركية مخروطية

الحصول على السعر والدعم Whatsapp +8618637198006 البريد الإلكتروني: zd-machine@kssb.cn الحصول على السعر ترك رسالة خط تجهيز الخام: الكسارة المخروطية الزنبركية مناسبة لسحق خام الحديد وخام النحاس والخامات المعدنية الأخرى في معالجة الخام.

هيدروليكي مخروط محطم

احصل على السعر والدعم Whatsapp +8618637198006 البريد الإلكتروني: zd-machine@kssb.cn احصل على السعر اترك رسالة،

كسارة سيمونز المخروطية

الحصول على السعر والدعم واتس اب +8618637198006 بريد إلكتروني: zd-machine@kssb.cn احصل على السعر ترك رسالة ,

كسارة المطرقة

احصل على السعر والدعم Whatsapp +8618637198006 البريد الإلكتروني: zd-machine@kssb.cn احصل على السعر اترك رسالة،

لفة كسارة

احصل على السعر والدعم Whatsapp +8618637198006 البريد الإلكتروني: zd-machine@kssb.cn احصل على السعر اترك رسالة،

كسارة الأسنان

احصل على السعر والدعم Whatsapp +8618637198006 البريد الإلكتروني: zd-machine@kssb.cn احصل على السعر اترك رسالة،

كسارة مركبة

الحصول على السعر والدعم واتس اب +8618637198006 بريد إلكتروني: zd-machine@kssb.cn احصل على السعر ترك رسالة ,

جار التحميل…

已经 是 到 最后 一篇 内容 了!

آلة التقسيم

آلة التقسيم